-

01 01

01 01Wind Tooling Catalog

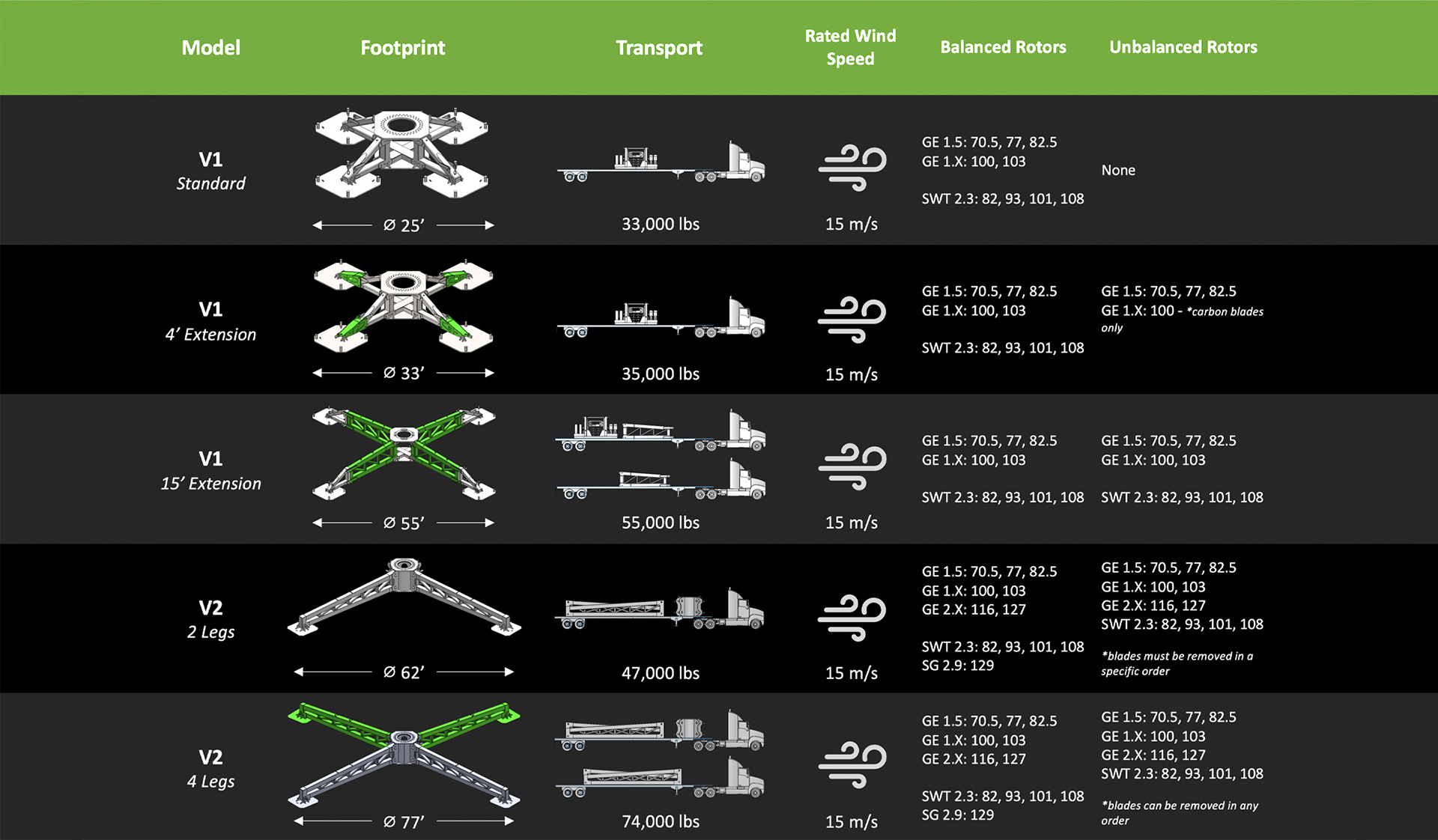

Specialized Tools for Wind Turbine Repair / Available for Rental or Purchase

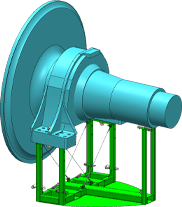

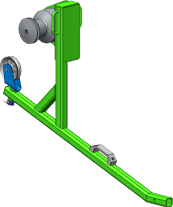

Not just a “can”! LiftWerx rotor stand are designed to secure rotors in high winds and requires no additional equipment to support blade tips.

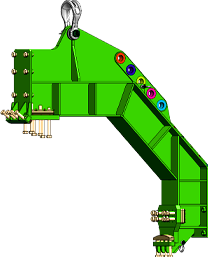

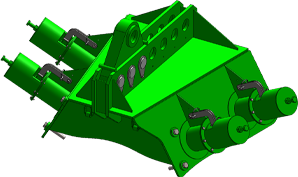

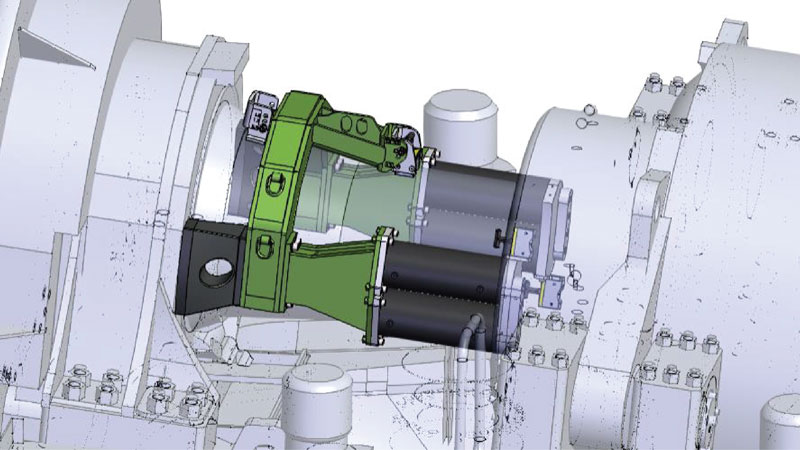

Exchange Gearboxes with Half the Crane Costs.

Systems from 50 – 400 tons for safely ejecting gearboxes and main shafts, even in the most extreme cases.

Perform gearbox repairs and IMS replacements without the need for traditional cranes.

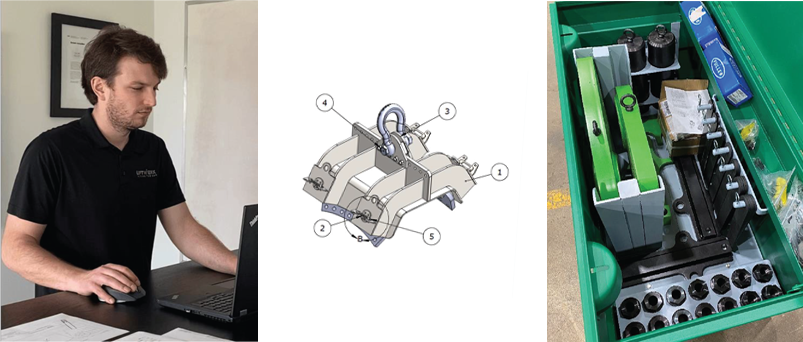

Kits available to meet your specific needs.

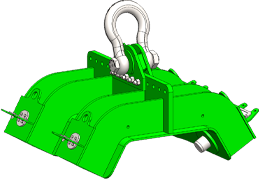

Need something you don’t see listed here?

LiftWerx creates custom solutions, such as lifting tools and rotor locking devices.

Let our team of experienced wind industry engineers and technical experts solve your problem.